Meeting significant productivity requirements while providing energy efficiencies.

Highly filled polymers are found in many different flooring materials, including PVC for luxury vinyl tile (LVT) and polyethylene (PE) with PVC for floor backing, along with added fillers to improve the polymer’s base mechanical properties and reduce production costs.

PVC, Polyvinyl Chloride, is the world’s third most widely produced synthetic polymer and is used extensively in building and construction materials as well as a variety of flooring applications, including LVT.

The addition of calcium carbonate, a common substance found in rocks as the minerals calcite and aragonite, as a filler improves the base properties of PVC and polyethylene by adding stiffness to the polymer matrix and improving impact resistance. This compound is used in the backing layer of LVT to reduce cost and improve mechanical properties.

Luxury vinyl tile (LVT) is an innovative design of vinyl flooring. It is becoming an increasingly popular and affordable alternative to wood, stone or ceramic tile. The realistic look is hard‑wearing and resilient to daily wear and tear with a scratch‑resistant and water-proof surface.

- All LVT layers are produced from PVC along with a selection of additives

- The upper sections are made of a thin protective and decorative sheet

- The lower layers are made of highly filled PVC for rigidity and durability

FARREL POMINI compounding equipment excels at the highly filled requirements of flooring, producing high volumes of material using less energy and reducing production costs. The world’s leading flooring brands use FARREL POMINI equipment.

Farrel Continuous Mixers are designed to address the many challenges of processing flooring compounds including:

- A single entry feed port and efficient rotor feed flight conveying capacity enable a high volume of material intake and processing

- The 6 L/D rotor design allows for low energy usage and specific energy input (SEI) as well as minimal residence time and heat history for the polymer

- Efficient shear provided by the rotor feed flight design, in addition to rotor cooling and multiple temperature control zones, process the polymer within its ideal temperature range and allow fill levels to be maximized

- Atmospheric venting and high free volume mixing chamber enable the high fill level mixing requirements

FARREL POMINI Nominal Production Rates for Flooring Compounds

| Application | CP250 | CP550 | CP1000 | CP2000 | CP2500 | CP4000 | 9UM Line |

|

|---|---|---|---|---|---|---|---|---|

| Flooring | kg/h T p.a. |

230 - 250 920 - 1,000 |

500 - 550 2,000 - 2,200 |

900 - 1,000 3,600 - 4,000 |

1,800 - 2,000 7,200 - 8,000 |

2,400 - 2,600 9,600 - 10,400 |

3,800 - 4,200 15,200 - 16,800 |

6,500 - 7,000 26,000 - 28,000 |

*Based on 4000 hrs per year.

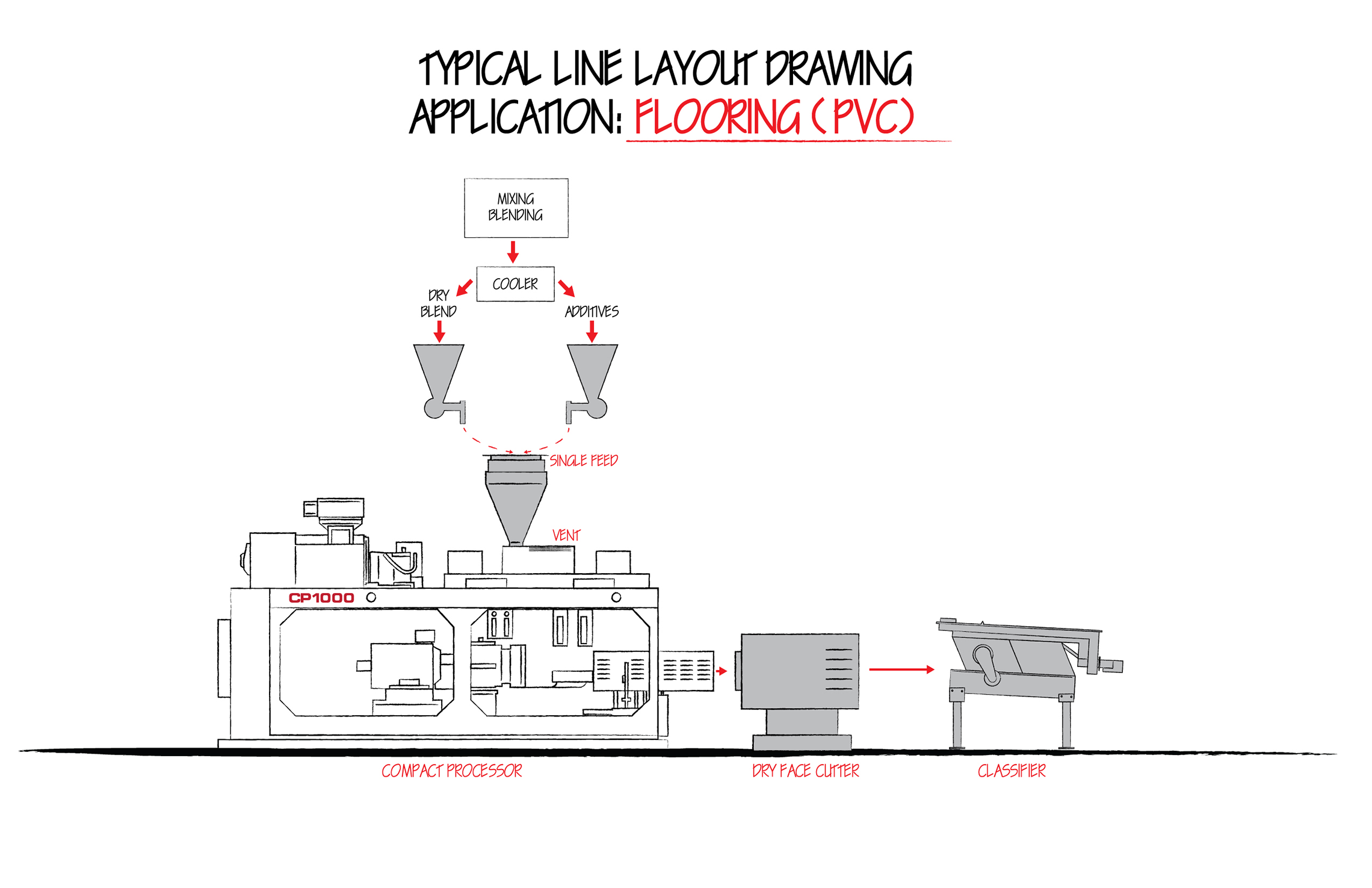

Typical plant line for flooring compounds

Would you like to learn more about our process expertise with Flooring Compound applications?

Contact us or call +1 203 736 5500 to speak with a Sales Engineer or schedule time in a Customer Demonstration Facility.

FARREL POMINI, your solutions provider.

LET OUR EFFICIENCY DRIVE YOUR SUCCESS.

Contact Us

Address:

Farrel Corporation

One Farrel Boulevard

Ansonia, Connecticut 06401-1256

USA