Applications

Highly Filled Masterbatch Compounding

Excellent dispersion and productivity while providing energy efficiencies.

Highly filled masterbatch, also known as natural or calcium masterbatch, contains high concentrations of calcium carbonate (CaCO3) or talc in the polymer base. These fillers modify polymer properties, for example, making a compound more structurally sound, and help to reduce costs by using a higher fill level.

Farrel Continuous Mixers are designed to address the many challenges of processing highly filled masterbatch including:

- A single-entry feed port and efficient rotor feed flight conveying capacity enable a high volume of material intake and processing

- The 6 L/D rotors allow for additional energy cost savings due to the short residence time and lower specific energy imparted into the materials, while the unique rotor geometry ensures optimum dispersion of the filler into the polymer

- The high free volume mixing chamber allows for maximum filler levels and material circulation

- Separate and independent mixing and pressurization, or extrusion, functions ensure each process is performed at optimum conditions resulting in low specific energy input (SEI)

- A variety of production sizes to meet large throughput requirements for economies of scale and productivity

FARREL POMINI Nominal Production Rates for Highly Filled Masterbatch Compounding

| Application | CP250 | CP550 | CP1000 | CP2000 | CP2500 | CP4000 | 9UM Line |

|

|---|---|---|---|---|---|---|---|---|

| Calcium Masterbatch | kg/h T p.a. |

230 - 250 920 - 1,000 |

500 - 550 2,000 - 2,200 |

900 - 1,000 3,600 - 4,000 |

1,800 - 2,000 7,200 - 8,000 |

2,400 - 2,600 9,600 - 10,400 |

3,800 - 4,200 15,200 - 16,800 |

6,500 - 7,000 26,000 - 28,000 |

*Based on 4000 hrs per year.

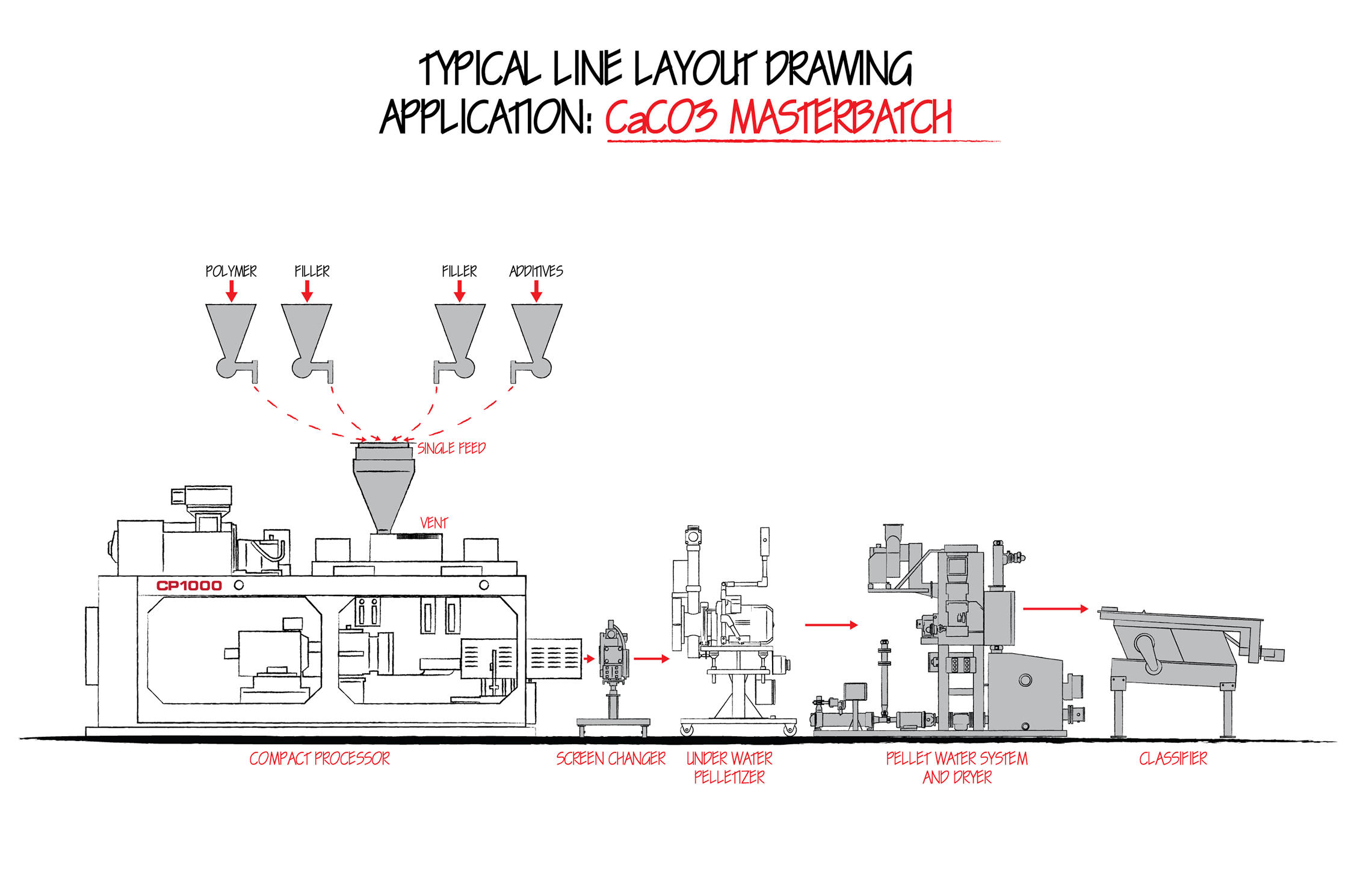

Typical plant line for highly filled masterbatch

Would you like to learn more about our process expertise with Highly Filled Masterbatch applications?

Contact us or call +1 203 736 5500 to speak with a Sales Engineer or schedule time in a Customer Demonstration Facility.

FARREL POMINI, your solutions provider.

LET OUR EFFICIENCY DRIVE YOUR SUCCESS.

Contact Us

Address:

Farrel Corporation

One Farrel Boulevard

Ansonia, Connecticut 06401-1256

USA