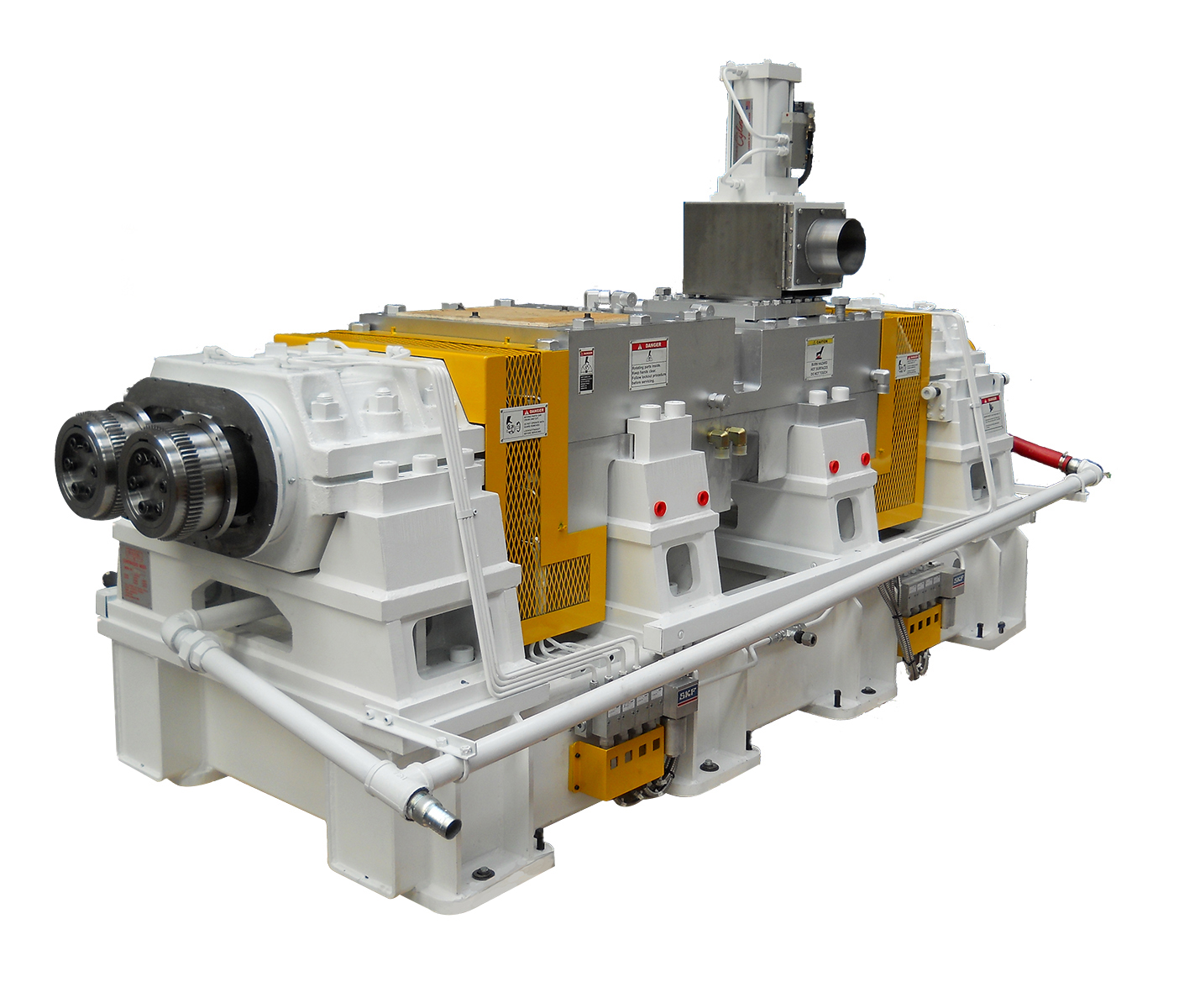

Modular design provides superior compounding, process efficiencies and accelerated return on investment.

Farrel, the Originator of Continuous Mixing Technology.

Farrel first introduced the FCM™, Continuous Mixer in 1963. Continuous Mixing Technology is based on the principle of two counter-rotating, non-intermeshing rotors and a large free volume mixing chamber. The large mixing chamber allows for liberal material circulation and superior distributive mixing, while the specialized rotor geometry facilitates efficient levels of shear and excellent dispersive mixing.

Continuous Mixing is a unique technology alternative to conventional compounding technologies and excels when compounding highly filled, temperature-sensitive and abrasive polymers. The FCM™ provides a long machine lifecycle, significant energy, process and maintenance efficiencies, and maximum on-stream time-critical to successful volume-driven compounding.

Other key features include:

- A single large feed port that allows for high fill loadings and irregularly sized materials

- Mixing intensity that can be adjusted by making changes to rotor speed, working volume, thermal conditions and orifice position

- The standard 6 L/D provides a short residence time and low heat history for the polymer while still providing a high-quality mixture at the exit of the processor

- Wide operating window

- Modular components for easy maintenance and greater productivity time

- Custom options available to suit individual applications

FCM™, Farrel Continuous Mixer Capacities

| Machine Size | 4UM | 5UM | 6UM | 7UM | 9UM | 12UM | 13UM | 16UM | 18UM |

|---|---|---|---|---|---|---|---|---|---|

| Nominal Production Rates (in kg/h)* |

400 to 700 |

800 to 1,300 |

1,500 to 2,500 |

2,000 to 3,500 |

3,000 to 7,000 |

5,000 to 14,000 |

8,000 to 18,000 |

15,000 to 25,000 |

20,000 to 40,000 |

*All production rates should be factory verified.

Would you like to learn more about our technology?

Contact us or call +1 203 736 5500 to speak with a Sales Engineer or schedule time in a Customer Demonstration Facility.

FARREL POMINI, your solutions provider.

LET OUR EFFICIENCY DRIVE YOUR SUCCESS.

ensures:

Contact Us

Address:

Farrel Corporation

One Farrel Boulevard

Ansonia, Connecticut 06401-1256

USA