Products

FARREL POMINI Compounding & Extrusion Systems

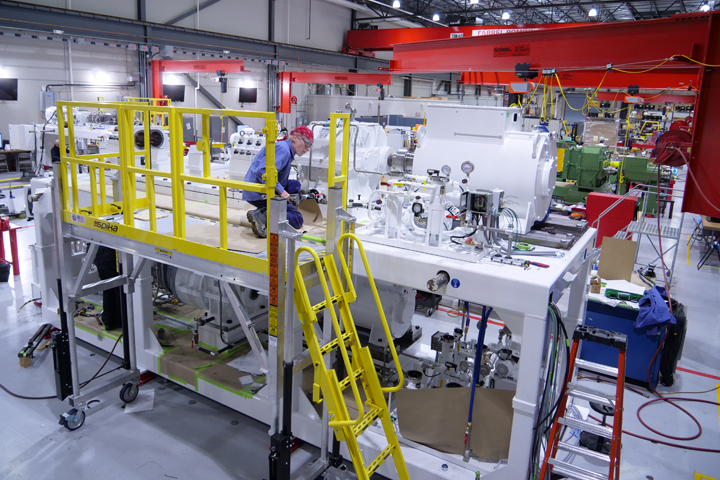

For polymer processing’s most demanding applications, FARREL POMINI equipment is unique and offers significant benefits.

FARREL POMINI is a global leader in the research, design, and manufacture of compounding systems for highly filled and temperature-sensitive polymer applications. Our unique equipment allows for superior energy and maintenance efficiencies, wide processing window, maximum on-stream time and accelerated return on investment.

All FARREL POMINI equipment is assembled and tested in our US facility to rigorous quality standards.

Would you like to learn more about our technology?

Contact us or call +1 203 736 5500 to speak with a Sales Engineer or schedule time in a Customer Demonstration Facility.

FARREL POMINI, your solutions provider.

LET OUR EFFICIENCY DRIVE YOUR SUCCESS.

Contact Us

Address:

Farrel Corporation

One Farrel Boulevard

Ansonia, Connecticut 06401-1256

USA