Meeting critical highly filled requirements

for fire prevention in plastics.

Producing halogen free flame retardant (HFFR) materials relies on formulating compounds that meet specific performance criteria for fire prevention and conform to frequently updated compliance regulations. Compounding for flame retardance requires high fill levels to be processed at controlled temperatures. Several retarding materials are used as fillers to moderate flammability, heat release, reduce smoke and fume generation:

- Alumina Trihydrate (ATH), the world’s most widely used flame retardant has a metal hydroxide base. At temperatures above 200 °C, the three water molecules of ATH are released in an endothermic reaction, quenching the surface of surrounding materials to provide flame retardance and smoke suppression.

- Magnesium Hydroxide (MDH) is also metal hydroxide based and provides flame retardance similar to ATH however, MDH has an activation temperature above 330 °C. It is free of halogens or heavy metals.

- Polymeric Brominated Flame Retardant (BFR) is usually styrene-based and produced synthetically; it has an inhibitory effect on combustion chemistry and reduces the flammability of products containing them. Their chemical properties can vary greatly.

- Flame Retardant Compounds are a concentration of flame retarding materials in a carrier of binder designed for a specific application. Typical carriers used are Low-density polyethylene (LDPE), Ethylene-vinyl acetate (EVA), High-density polyethylene (HDPE), and Polypropylene (PP).

Farrel Continuous Mixers are designed to address the many challenges of flame retardant and HFFR processing including:

- A single entry feed port and divert from the mixing chamber that reduces contamination potential

- Rotor feed flights for efficient shear plus multiple temperature control zones and rotor cooling for processing the polymer within its ideal temperature range allows fill levels to be maximized

- Adjustable rotor speed during production facilitates excellent quality and dispersion

- A large free volume mixing chamber for material circulation enables superior distribution and dispersion

Using flame retardant materials for a variety of products

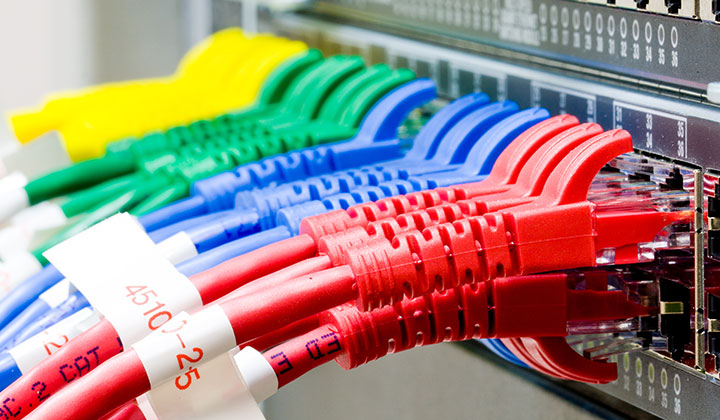

Fire can be mitigated by incorporating flame retardant materials, including ATH, MDH, BFR and others, into resins such as polyolefins that offer excellent insulation in electrical wiring, but the polymer on its own can be highly combustible. Common applications include:

- Wiring (ATH and MDH)

- Construction (BFR)

- Flooring (ATH and MDH)

- Insulation (BFR)

FARREL POMINI Nominal Production Rates for HFFR & Flame Retardant Compounds

| Application | CP250 | CP550 | CP1000 | CP2000 | CP2500 | CP4000 | 9UM Line |

|

|---|---|---|---|---|---|---|---|---|

| Flame Retardants | kg/h T p.a. |

170 - 190 680 - 760 |

350 - 400 1,400 - 1,600 |

600 - 800 2,400 - 3,200 |

1,200 - 1,500 4,800 - 6,000 |

1,200 - 1,500 4,800 - 6,000 |

2,800 - 3,000 11,200 - 12,000 |

5,000 - 5,500 20,000 - 22,000 |

*Based on 4000 hrs per year.

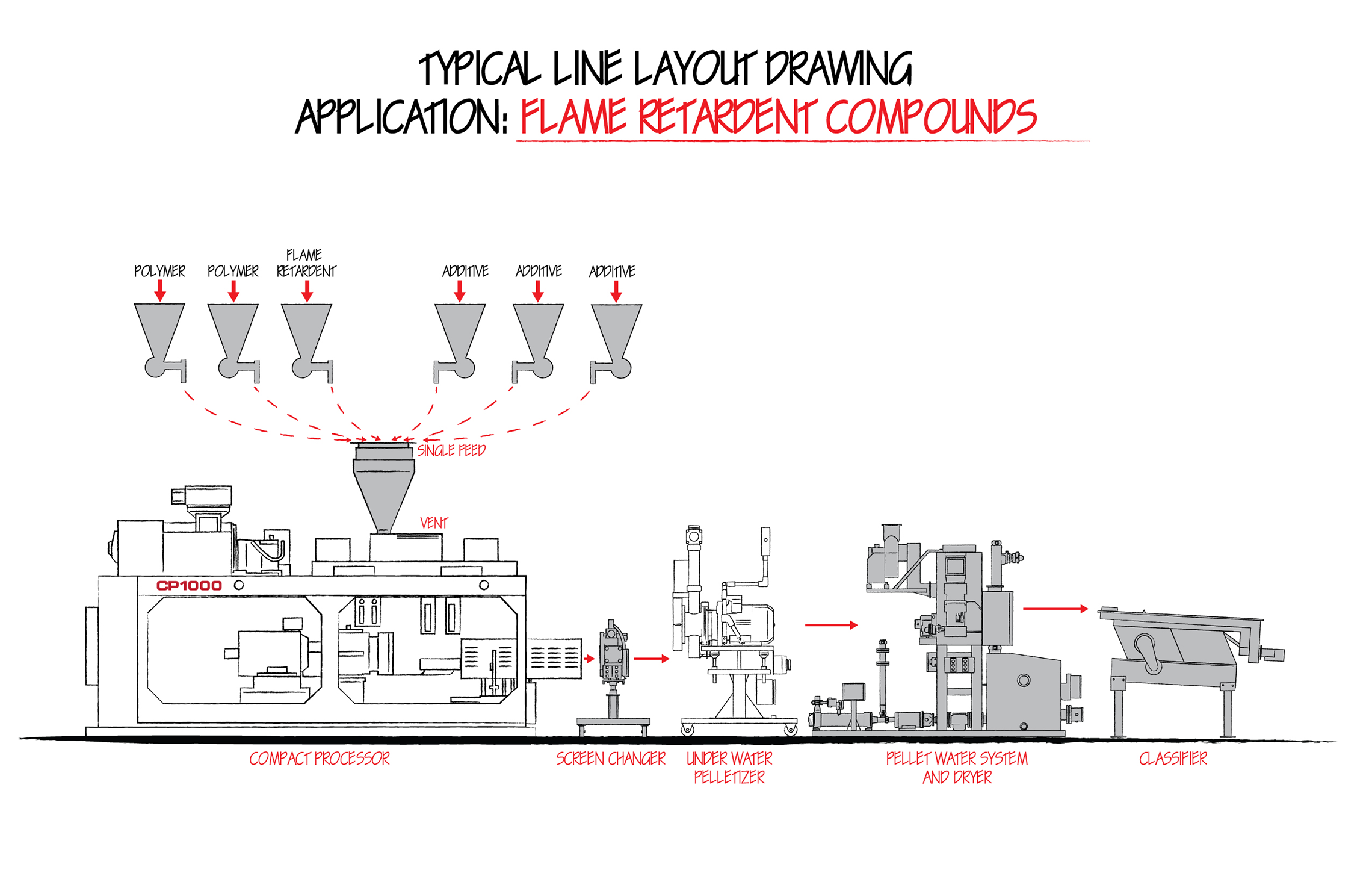

Typical plant line for flame retardant compounds

Would you like to learn more about our process expertise with HFFR & Flame Retardant applications?

Contact us or call +1 203 736 5500 to speak with a Sales Engineer or schedule time a Customer Demonstration Facility.

FARREL POMINI, your solutions provider.

LET OUR EFFICIENCY DRIVE YOUR SUCCESS.

Contact Us

Address:

Farrel Corporation

One Farrel Boulevard

Ansonia, Connecticut 06401-1256

USA