Compounds and extrudes highly filled,

temperature sensitive and abrasive

materials with low processing temperatures.

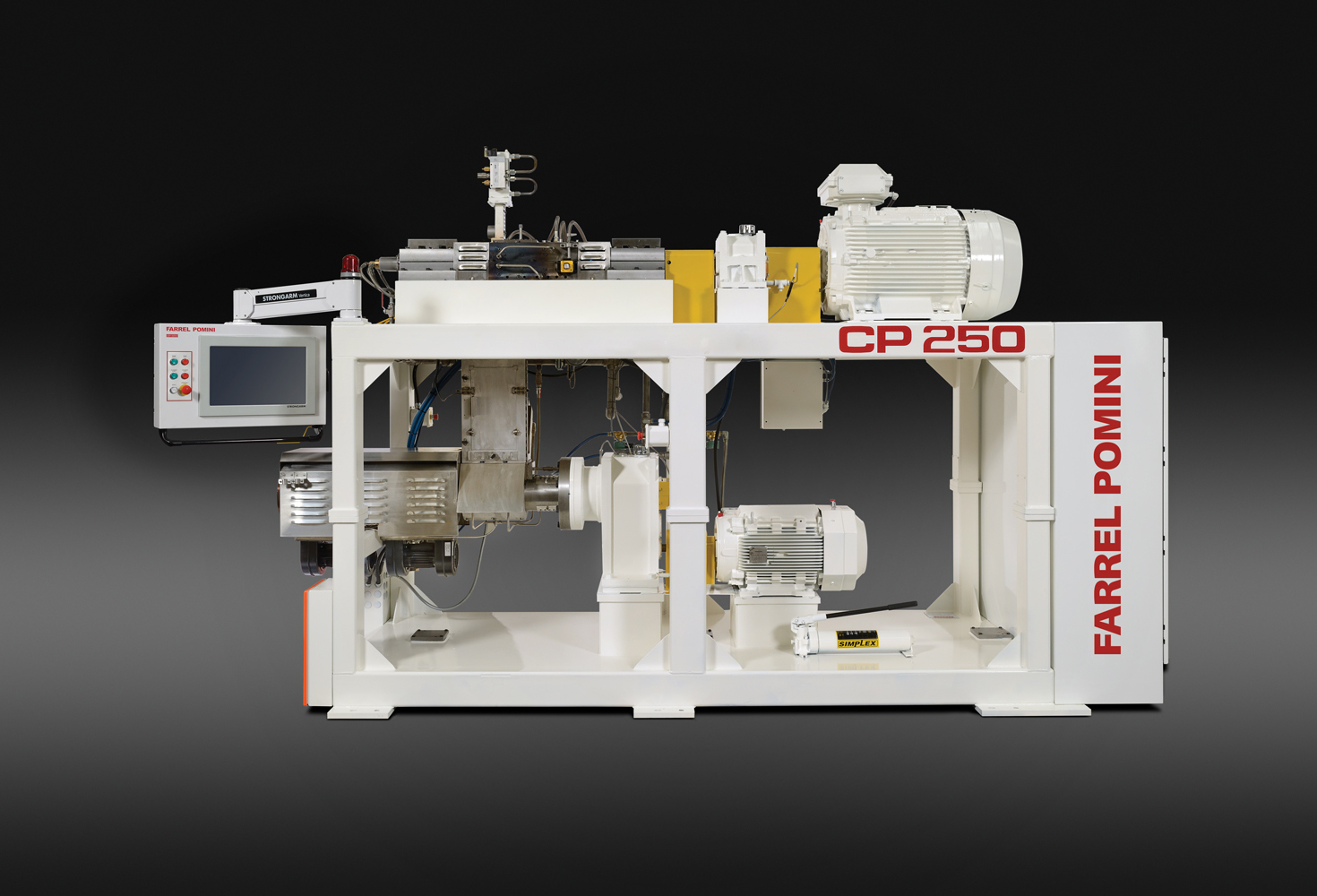

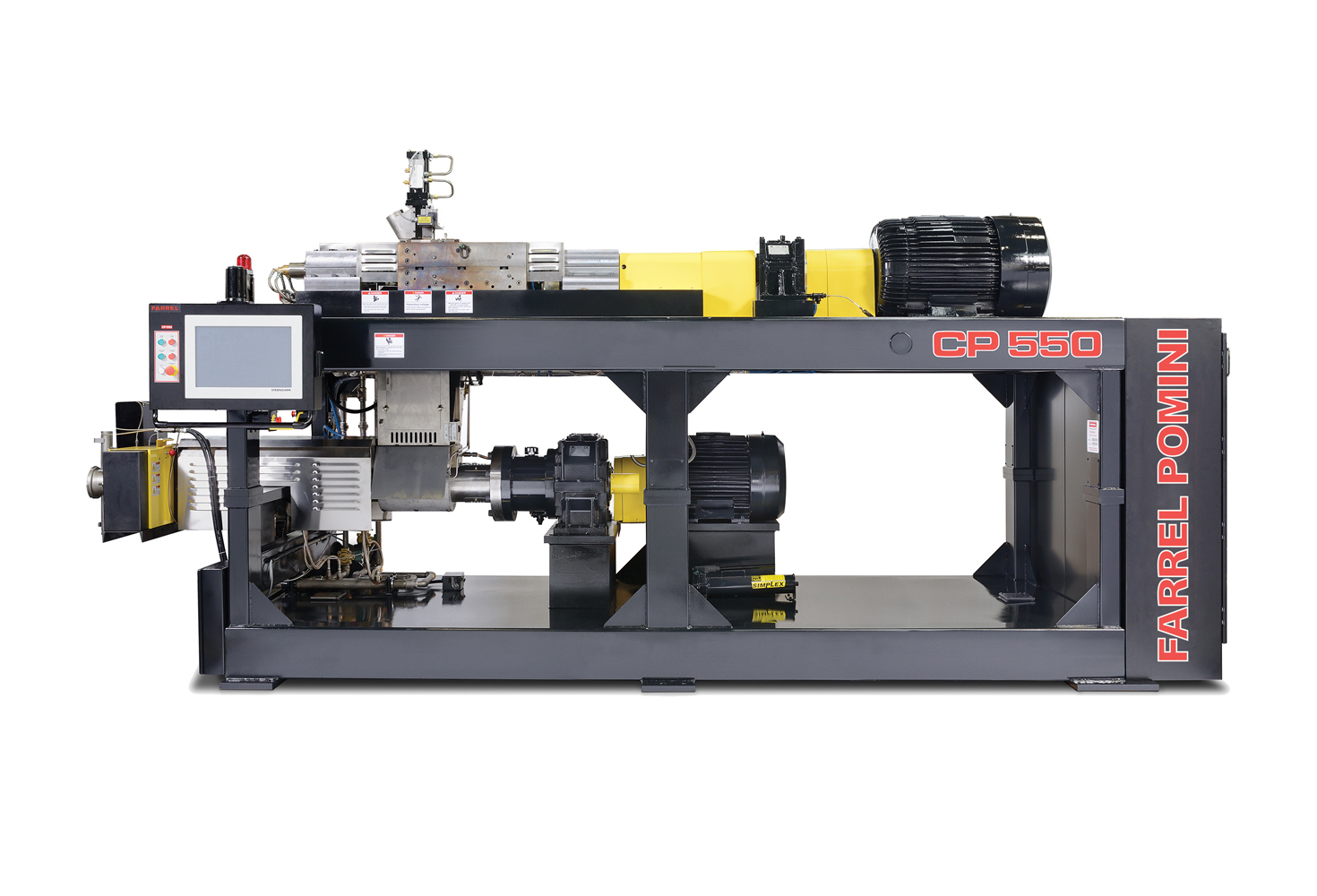

The CP Series II™ Compact Processor with Continuous Mixing Technology is unique to the polymer conversion industry, offering high-performance compounding with the ability to convert highly filled, temperature-sensitive and abrasive materials at low processing temperatures. The extremely productive CP Series II™ is designed specifically for excellent polymer dispersion and distribution resulting in a reliably homogeneous, thermally consistent compound.

The independently controlled compounder and extruder are designed to incorporate various types of feeding systems and pellet formation components for exceptional versatility and a range of applications. Mounted on a single frame, the FARREL POMINI CP Series II™ Compact Processor is fully wired, piped, pre-tested and ready for installation.

CP Series II™ Key Features Include:

- Two counter-rotating, non-intermeshing rotors providing efficient levels of shear and excellent dispersive mixing

- The mixing chamber incorporates numerous features that enhance processing performance, operation and maintenance

- A hot feed pumping extruder separated from the mixing chamber

- Modular components allow for easy maintenance and maximum on-steam time

- The user-friendly FARREL POMINI Synergy™ Control System, with remote monitoring and support capabilities, can be set to automatic or adjusted manually during operation

- Wide operating window

- Custom options available to suit individual applications

CP Series II™ Compact Processor Capacities

| Machine Size | CP125 | CP250 | CP550 | CP1000 | CP2000 | CP2500 | CP4000 |

|---|---|---|---|---|---|---|---|

| Nominal Production Rates (in kg/h)* |

70 to 150 |

150 to 300 |

400 to 700 |

800 to 1,300 |

1,500 to 2,500 |

2,000 to 2,750 |

2,500 to 5,000 |

*All production rates should be factory verified.

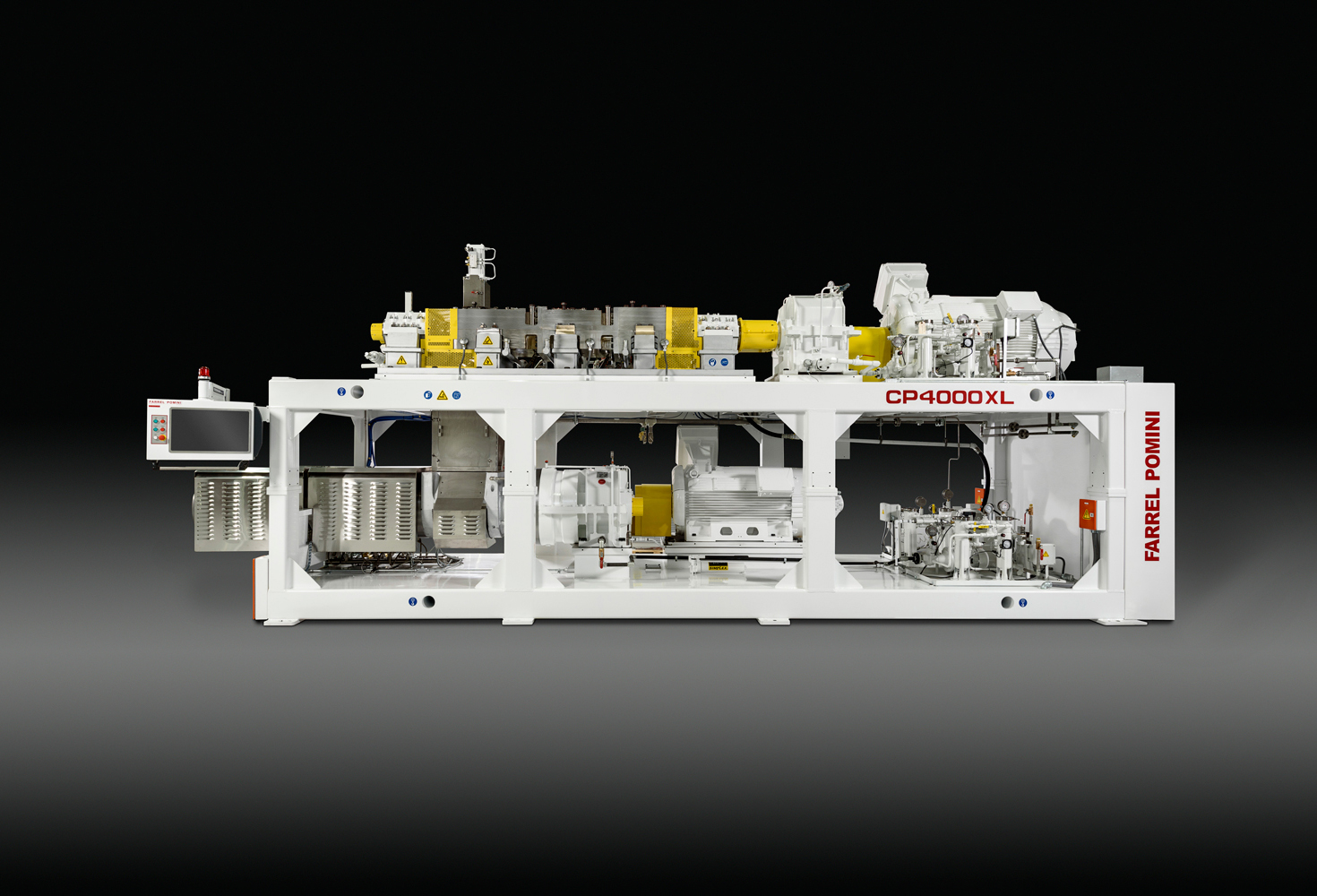

CP Series II™ XL, Long Continuous Mixer Capacities

The CP Series II™ XL incorporates Pomini LCM technology into the CP Series II™ product family. It provides LCM performance and allows processing options for specific applications.

| Machine Size | CP550XL | CP1000XL | CP2000XL | CP2500XL | CP4000XL |

|---|---|---|---|---|---|

| Nominal Production Rates (in kg/h)* |

400 to 500 |

800 to 1,000 |

1,500 to 2,400 |

2,000 to 2,750 |

2,500 to 5,000 |

*All production rates should be factory verified.

Would you like to learn more about our technology?

Contact us or call +1 203 736 5500 to speak with a Sales Engineer or schedule time in a Customer Demonstration Facility.

FARREL POMINI, your solutions provider.

LET OUR EFFICIENCY DRIVE YOUR SUCCESS.

ensures:

Contact Us

Address:

Farrel Corporation

One Farrel Boulevard

Ansonia, Connecticut 06401-1256

USA