Sustainability through innovation.

We promote an energy efficient circular economy.

Our systems don’t promise change. They enable it. FCM™, Farrel Continuous Mixing technology is enhancing circularity in the plastics industry with unique compounding, masterbatch, and recycling solutions.

Our theme for K2025 is clear: sustainability through innovation. We will feature a range of technologies and demonstrations that showcase how FARREL POMINI® is advancing sustainable solutions in the plastics industry.

Visit us at K2025

Hall 9 Stand A16.

Learn how to move forward with our solutions. Discuss your possibilities with our experts.

Not going to K? No problem. Use this form to schedule a call at your preferred time.

Schedule your best date for a meeting.

Book Your MeetingHighlights at K2025

CPeX® Laboratory Compact Processor

A lab scale compounder utilizing the proven FARREL POMINI® continuous mixing technology. With a nominal throughput of 30 kg/hour and both standard and CPXL rotor configurations, the CPeX® enables rapid product development, application testing,

and time-to-market reduction.

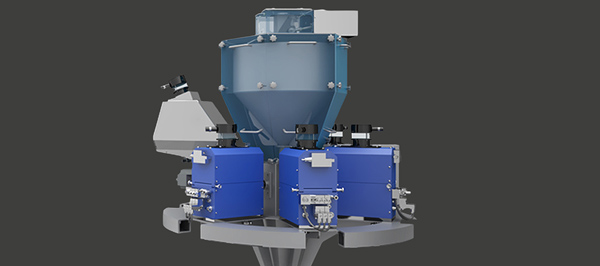

Ampacet Corporation SpectroMetric™ 6 In-line Color Correction Feeding System

Displayed along with the CPeX®, this system maximizes post-consumer recycled content usage while maintaining precise color control.

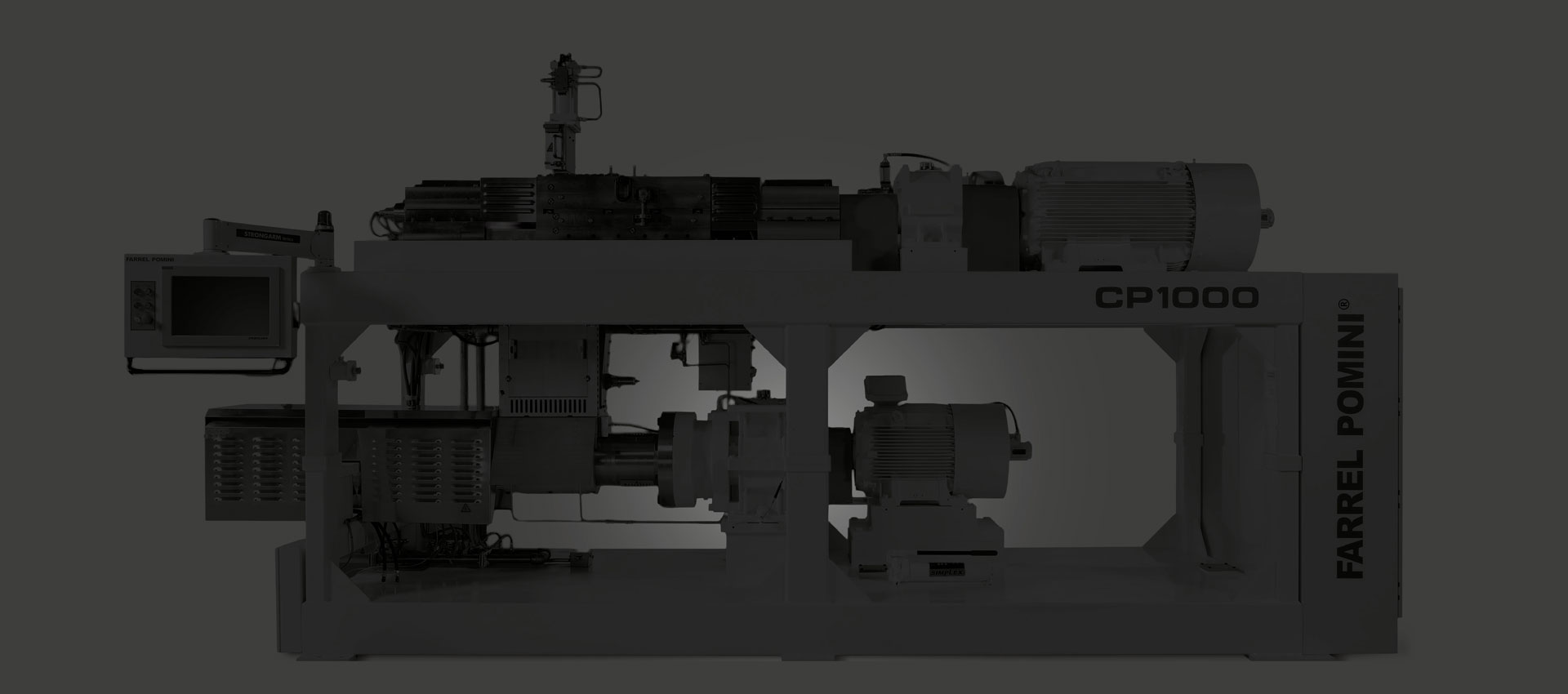

Augmented Reality Demonstration of the

CP Series II™ Compact Processor

Experience a virtual walk-through of the CP Series II™, including detailed views of the feed

hopper,

rotors, and mixing chamber, offering deeper insight into its mechanical design and

performance.

OCTOBER 8 – 15, 2025; K Hall 9 Stand A16 Düsseldorf, Germany

Recycling Station at K2025 features:

Mechanical Recycling with the Farrel Continuous Mixer

A video presentation of the complete solution including a large feed hopper for ingestion of irregularly shaped material, crammer options for low bulk density feeding, proprietary hard surface coatings for maximum wear, a patent-pending grooved mixer feed section and a vent capture system. Mechanical recycling on the Farrel Continuous Mixer is achieved with similar exceptional energy efficiencies of other applications and at nominal production rates.

Pyrolysis for Plastics with Lummus Technology

The presentation will outline the role of FARREL POMINI® in a patented plastics pyrolysis process developed by Lummus Technology. The process handles mixed plastic waste streams for shredding, cleaning, and melting. The Farrel Continuous Mixer prepares the feedstock for pyrolysis, contributing to a circular economy by converting plastic waste into valuable resources.

WF RECYCLE-TECH Presentation

The feature details their patented pyrolysis system addressing the critical global subject of tire recycling. The WF system utilizes the FCM™, Farrel Continuous Mixer for pre-processing of the crumb material prior to the pyrolysis step.